Scale Your Business With These New Opportunities

Is your 2024 growth strategy geared towards expanding on various marketplaces? At ShipStation, we’ve observed that customers who tap into new selling channels witness incremental sales growth. Discover exciting opportunities, including the popular open-source platform Shopware, and our support for international orders through Global-e on Shopify Markets Pro. Explore a range of marketplaces in our partner directory and elevate your business through strategic marketplace integration. Join us in unlocking new avenues for success!

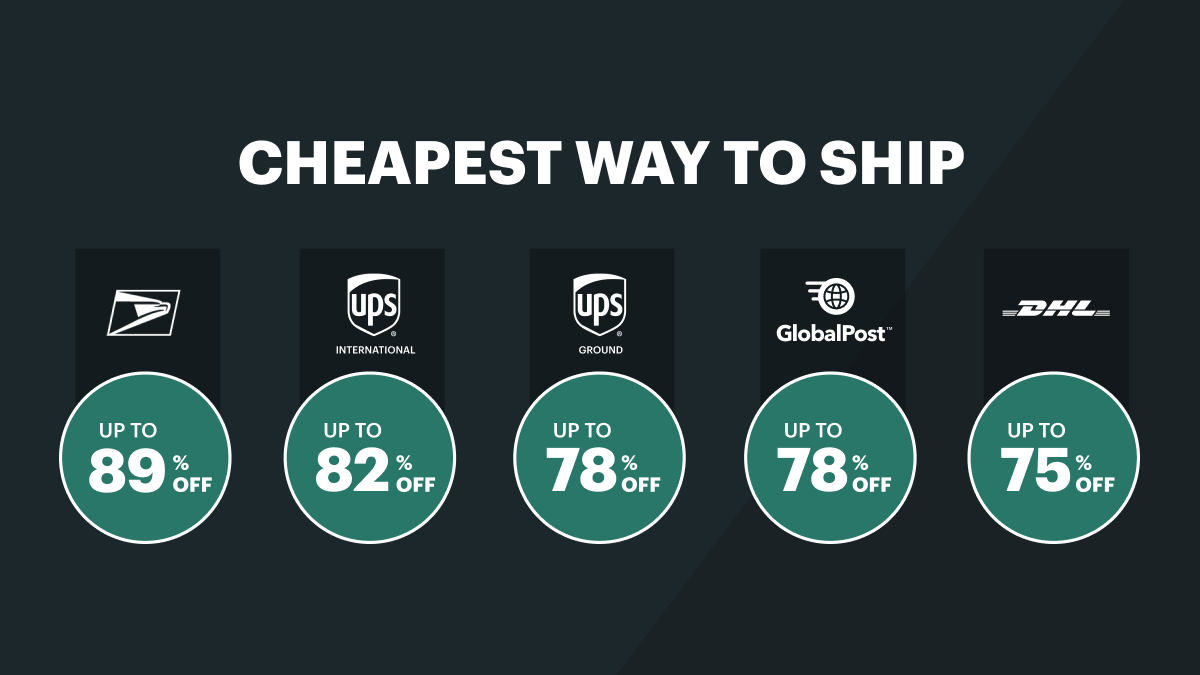

Access Carrier Service Discounts

With ShipStation Carrier Services, you can access discounts for a range of shipping services. Learn how Veiled Collection optimized warehouse operations and saved 30% on shipping using ShipStation and UPS® Ground Saver.

Try New Additions to Amazon Integrations

Explore the latest additions to our Amazon integration. You can now print Amazon Shipping ground delivery labels in ShipStation and also leverage Amazon’s fulfillment network to deliver orders from off-Amazon channels with Amazon Multi-Channel Fulfillment.

Automate Returns

Dealing with those post-holiday returns? Set yourself up to automate returns and optimize the shopper experience for exchanges ahead of refunds with Return Rabbit.

Expand Into New Marketplaces

Does your 2024 growth strategy include selling on more marketplaces? We’ve found ShipStation customers who add new selling channels gain incremental sales for each additional channel. Explore our new opportunities including Shopware, a popular open source platform, and we now support international orders with Global-e on Shopify Markets Pro. You can find a full range of marketplaces on our partner directory.